Marine Heat Tube Exchanger

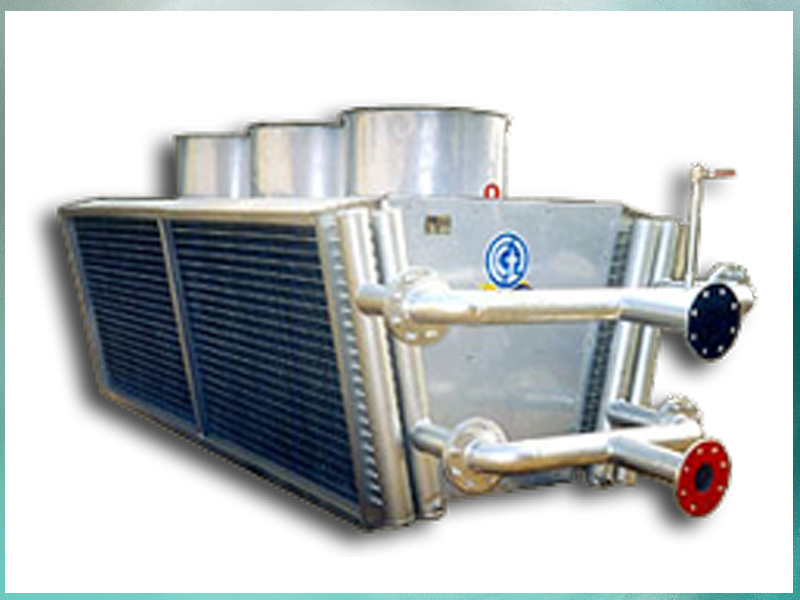

Heat Transfer equipments Air Cooled Condenser Manufacturers India

Heat Transfer equipments Equipments are certified ISO and ASME (The American Society of Mechanical Engineers) company with 23 years experience in Heat Exchanger Industry. We are manufacturing of heat exchangers since 1990. Heat Transfer equipments Equipments are speacially designed and developing of Air Cooled Condenser for all types of Thermal Power plants and indusries, Oil Plants and Gas Plants. Heat Transfer equipments has the good quality manufacturers and installing capability to supply the most excellent air cooled condenser for every applications.

Air Cooled Condensers Types are : Natural Convection and Forced Convection.

Components of Air Cooled Condenser System

- Ejectors

- 3Bellows

- Instrumentation

- Pipe Lines

- Strainers

- Valves

- Civil construction

- Cleaning system

- Fans ,Motor and Gear box

Parts of Air Cooled Condenser System

- Expansion bellows

- Hogger Ejection system

- Condensate extraction pumps

- Drain pot Pumps

- Inter condenser

- After condenser

- Condensate storage tank

- Gland steam condenser

- Drain Pot

Difference Between Air Cooled Condenser and Water Cooled Condenser Air Cooler

An air condenser is generally a lesser amount of valuable for condensing gases, for the reason that of the slower cooling time. However, if the gases are extremely hot, the icy water be able to cause the condenser to crack.

Air cooled condenser remove heat by blowing air over the condenser coil. The Air cooled condensers, as well referred to the same as “fin and tube” condensers, are in all probability the most able to be seen component in an air conditioning system, be it a room or packaged air conditioner or a packaged chiller.

If the condenser has water curving interested in the top part first, it will just run in a straight line through and not cool the vapour. by means of filling it from the base, the water is forced into the condenser and fills it totally. Water cooled condenser remove heat by pouring water over the condenser coil.

Spares of Air Cooled Condenser

The below spare lines also have required valves for operation. By this way the continuous operation of Condensation system is ensured by Heat Transfer equipments Equipments Pvt Ltd.

- Inter and after condenser

- Ejectors

- Condensate extraction pump

- Drain pumps

Air Cooled Condenser Working Principle

Air Cooled Condensers Types

- Natural Convection

- Forced Convection.

Natural Convection occurs when a heater with a reduction of dense fluid is pressed left by a cooler denser fluid.

Forced Convection occurs when an outer force pushes a fluid, such the same as water of air, to create it move about and transfer heat.

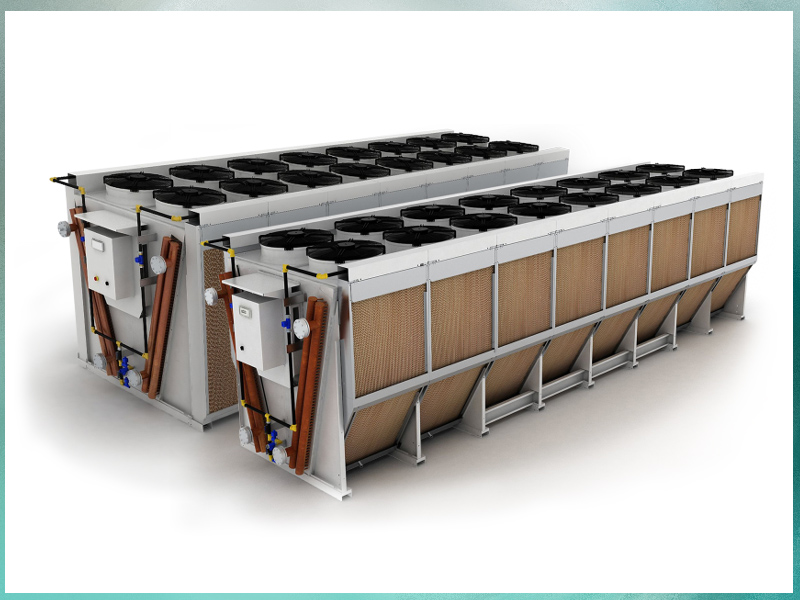

Air Cooled Condenser Design

- The nearly all accepted style of Air Cooled Condenser is the modularized (‘A’ frame structured design), used on industries and power plants of all sizes.

- Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries.

- The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries.

- The ‘A’ frame structured designs are mostly used in the power plants.

- Coil Design : Advanced Smart Circuitry Coil Technology

- Our Air Cooled Condenser Design Process Contains for Thermal Design.

Air Cooled Steam Condenser Problem

A successful air cooled steam condenser be required to continuously and totally gather and ejection all of the non condensables in the system. The non condensable are left behind inside the tubes and headers when the steam condensers

Applications of Air Cooled Condenser

- All Thermal power plants

- Gas based Plants

- Coal based plants

- Oil Plants

- Biomass power plants

- Refrigerant hot gas piping

- Nuclear power plants