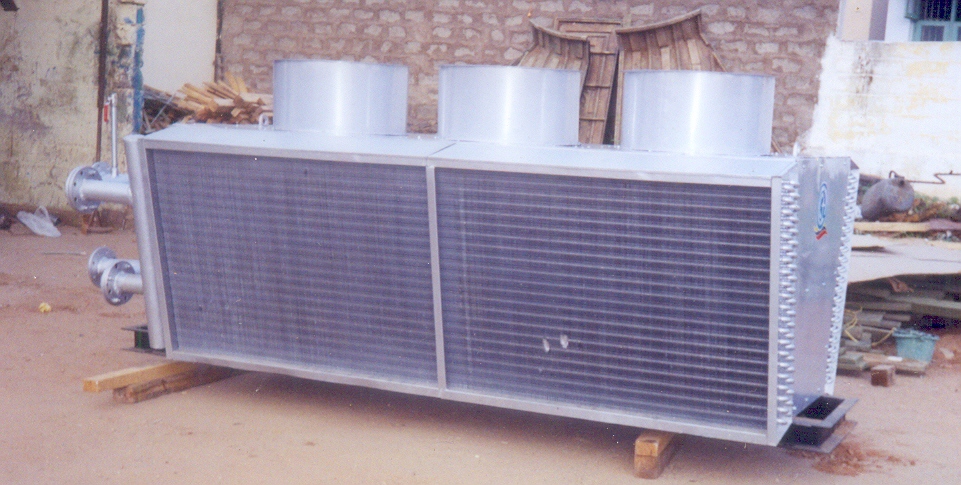

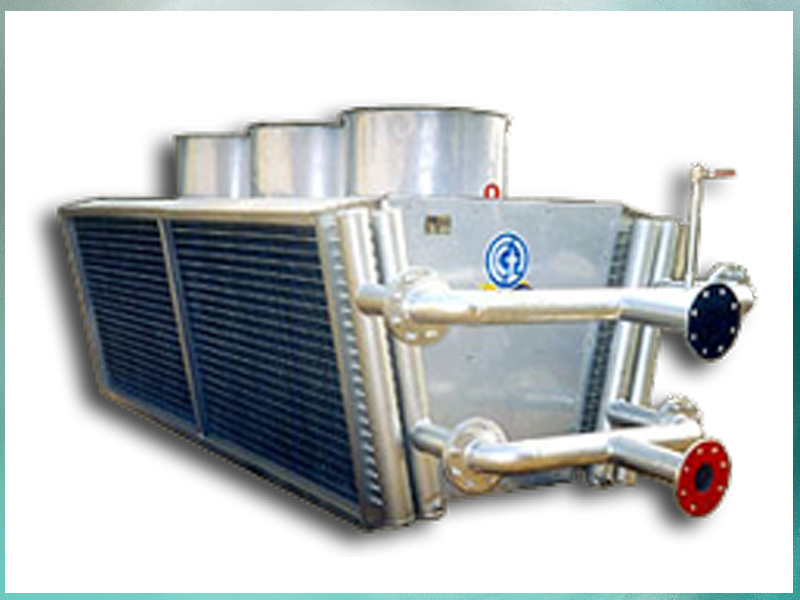

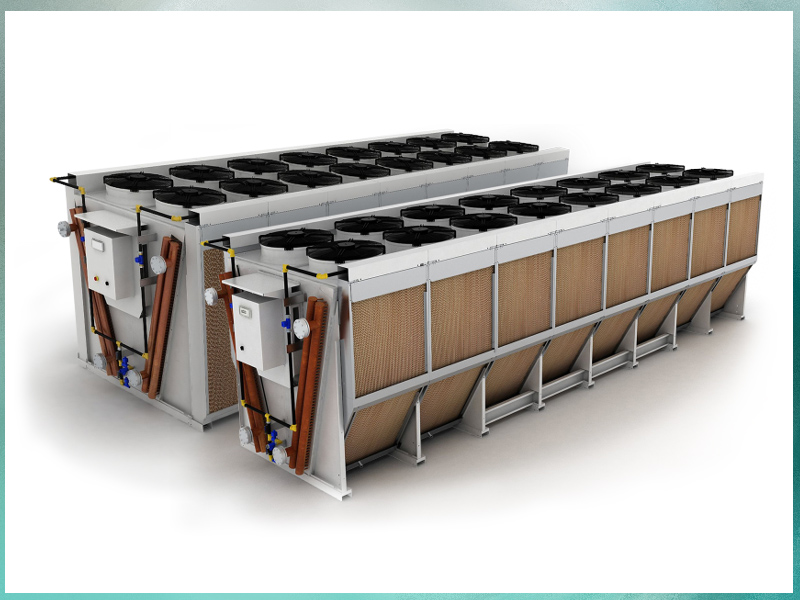

Dry cooling tower / Coil Cooling Tower is an equipment which is used to cool and maintain the temperature of process hot water at a particular level. This operates on the principle of heat transfer by a heat exchanger with extended fins. The fan is deiven by an Electric Motor. Applying dry cooling means saving water.

Dry cooling technologies prove technical qualities and effectiveness in power plant heat rejection.

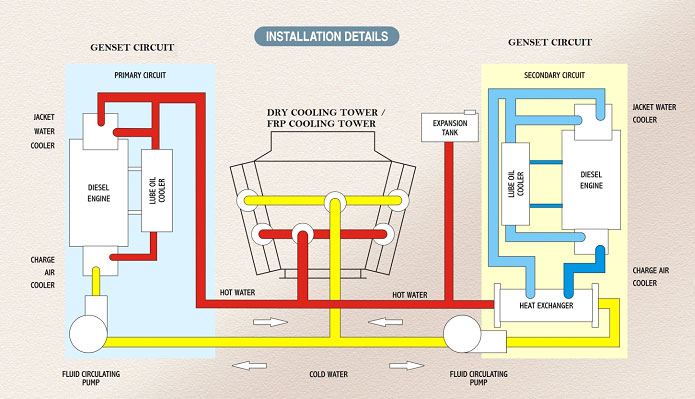

Dry Cooling Towers functioning in combination of extended sine wave finned surface heat transfer coils, with axial flow fans and rigid construction for regular operation. The hot water from any equipment can be sent to the inlet of the Dry Cooling Tower & that hot water get Cooled and Cold water outlet from the Dry / Coil is connected to the pump, which pumps the cold water to the equipment to transfer the heat from the equipment with less Evaporation loss, Maintenance free, No need of raw Water tank & 100% free from descaling.

Dry cooling benefits are:

- Conserving significant amount of water.

- Minimizing environmental impact.

- Very economical in cost.

Dry cooling Applications are:

- Power Plant Cooling Solution

- Injection Moulding

- Chemical & Oil Refineries

- Plastic Extruder Plant

- Steel Foundry & Forgings

- Dairy & Dyeing Plants

- Water Treatment Plants

- Diesel / Gas Genset Plants

Necessity of Air /Dry / Coil Cooling Tower

Water is the most essential element of our life, About 97 percent of that is stored in ocean. Of the remaining 3%, 2% are frozen ermanently as ice. What is left is what we have to work with. And this precious and meager amount needs a lot of attention to perform its function properly in the machines of civilization. Water plays a great role in industries. It is used as a coolant in various machineries. In water cooling towers like FRP Tower or Timber Tower, huge loss of water due to drift, evaporation, spray loss and blow down. It is now abundantly clear that water charges will go on rising at well beyond inflation rates. So for that we are introducing the Dry Cooling Tower / Coil Cooling tower for save the water.

1 Special Features of Air / Dry / Coil Cooling Tower

1.1 Usage :

The Air / Dry / Coil Cooling Tower are very compact and aerodynamically designed for Diesel Engines and LT & HT Circuits.

1.2 Very Less Water Conceptions:

The Air / Dry / Coil Cooling Tower are air cooled equipment so just you fill very small quantity of water, after that it is not required additional water. Due to the closed circuit there is no evaporation loss. So our towers are save the water cent percent.

1.3 Filling Water :

You can fill any typeor quality of water. No need of water softening plant or treatment chemicals. In first time just you fill small quantity of common drinking water.

1.4 No Scale formation

Due to closed circuit, same water will be circulated continually and no chance for evaporation so that scale will not be separate from the water and it is not deposit at any where in the heat transfer area.

1.5 Desiging:

Our Towers are very compact and aerodynamically designed. There is no any restriction for the location of the plant; atmospheric air is the cooling media. It cools the hot water and maintains the temperature of process hot water at a particular level. It has designed for highest ambient temperature so we could run the engine in 100% load even in peak summer. It has the fan and eectric motor to the water.

1.6 Energy Economy:

Our Towers are specially designed aerodynamically for power saving we are provide the mostat controls to switch off the fan motors in the time of cold ambient temperature.

1.7 Maintenance :

Our Dry Cooling Towers are closed circuit. So no chance to mix dust, fly, living organisms and dirt with process water. Air is the cooling media so there is no corrosion problem.

2. Technical Specifications of Dry / Coil / Air Cooling Tower

2.1 Designing and Material Quality

The Dry / Coil Cooling Tower are having heat transfer area with good quality coppers and very high quality of aluminium fins. Copper tubes are mechanically expended with coolers, it provides smooth inner tube surface so there is no chance for pressure drop (our Cooler are tested at 350 PSI). Coolers are favricated in heavy channels and using steel sheets. The finalized steel frame provides stacking and shipping support and production against tube damaging.

2.2 High performance of Fan and Motors:

A new generation start of the art cooling fans the energy economy concept. It combination of performance strength endurance and reliability designed aerodynamically for characteristic of the fan outlet essences an optimum distribution of air across the ” Cooler” giving an added benefit to the system fans are dynamically balanced on computerized machine. And using IP55 / TEFC standard motors.

Comparison chart between Dry Cooling Tower / Coil and Water Cooling Tower

Dry / Coil Cooling Tower

- Plant location restriction is not required

- Scale for mations are impossible

- Water consumption is not required

- No corrosions due to air

- Mixing of dust, dirt is not possible when processing of water

- Except fan and motors maintenance is negligible

Water Cooling Tower

- Water Source decides the location opf large plantsr

- Scale formation is unavoidable

- Huge loss of water due to evaporation, drift loss

- Steel parts in contact with water are corroded

- Water exposed to dust and dirt will be contaminated

- Maintenance is required

Note:

- The motor HP may be changed due to the ambient temperature of Air Cooling media and temperature of the water.

- Primary circuit inlet water temperature 80 C outlet water temperature 70 C. In secondary circuit inlet water temperature 66 C outlet water temperature 56 C

Dry Cooling Tower Advantages

- Eliminates Scale-formation

- Eliminates Contamination of air

- Eliminates Frequent maintenance

- Eliminates FRP Cooling Tower

- Eliminates make up water after the first fill

- Eliminates raw water Tank and Pumps.

- Eliminates Moving parts except fan & motor

- Eliminates Mixing of dust / dirt / fly ash with Water

- Eliminates PHE at Furnace & Coil circuit

- Eliminates de scaling, fungus cleaning Chemicals

- Eliminates water softening plant & chemicals

- Eliminates Heat exchanger headaches at primary circuit

- Eliminates maintenance cost, reduces power cost & saves earth