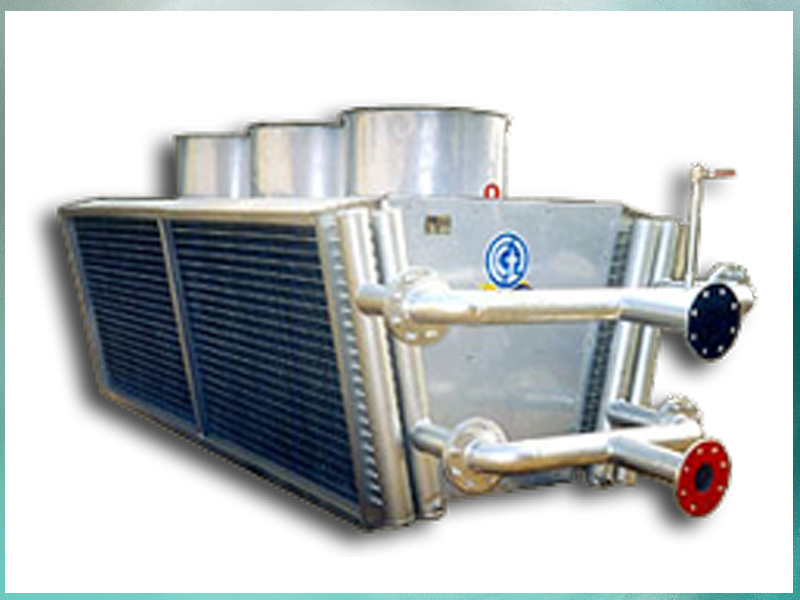

Closed Circuit Cooling Tower operate in a manner simillar to open cooling tower except that the heat load to be rejected is transfered from the process fulid to the ambient air through a heat exchange oil. The coil serves to isolate the process fluid from the outside air, keeping it clean and contaminate free in a closed loop. This creates two separate fluid circuits.

- a external circuit, in which spray water circulates over the coll and mixes with the out side, an internal circuit, in which the process field circulates inside the coil.

- During operation, heat is transfered from the internal circuit, through the coil to the spray water, and then to the atmosphere as a portion of the water, and then to the atmosphere as a portion of the water evaporates.

- During the time of shortage of cold water supply we have to go forClosed Circuit Cooling Tower. The cooling water is circulates in a close loop consisting tower unit.

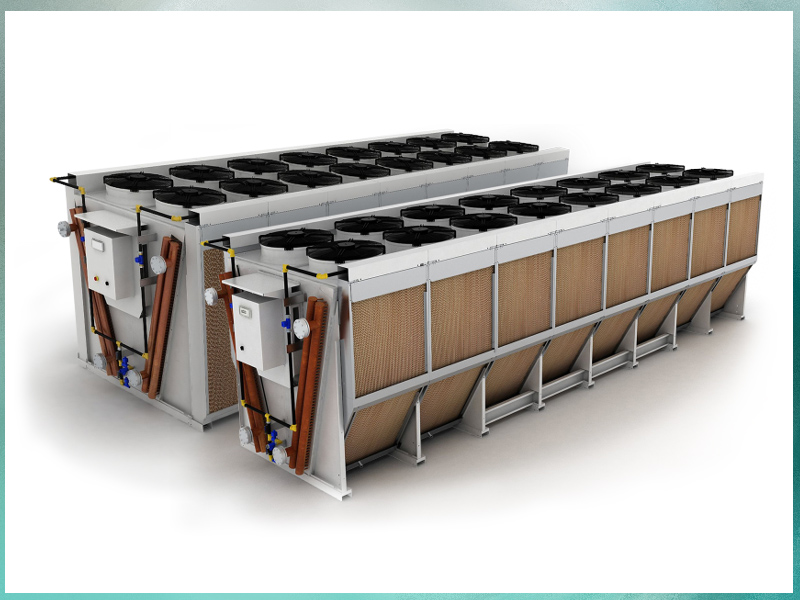

- We may add some percent of the cooling water from the available water resources to the closed circuit cooling system and we can reduce the cooling tower size.

- Mixing ration means the percentage of the added water. If our mixing ratio is zero, it is called completely closed system. When the mixing ratio is 100%, it is called an open system.

- Closed Circuit Cooling Tower are suitable for Thermal Power Plan