Heat Transfer Equipments Pvt Ltd, Coimbatore, Tamil Nadu, India, is a leading Manufacturer, Suppliers and Exporters of all types of FRP Cooling Towers, like FRP Square Type Cooling Tower, FRP Bottle Shape Cooling Tower, FRP Round type Cooling Towers.

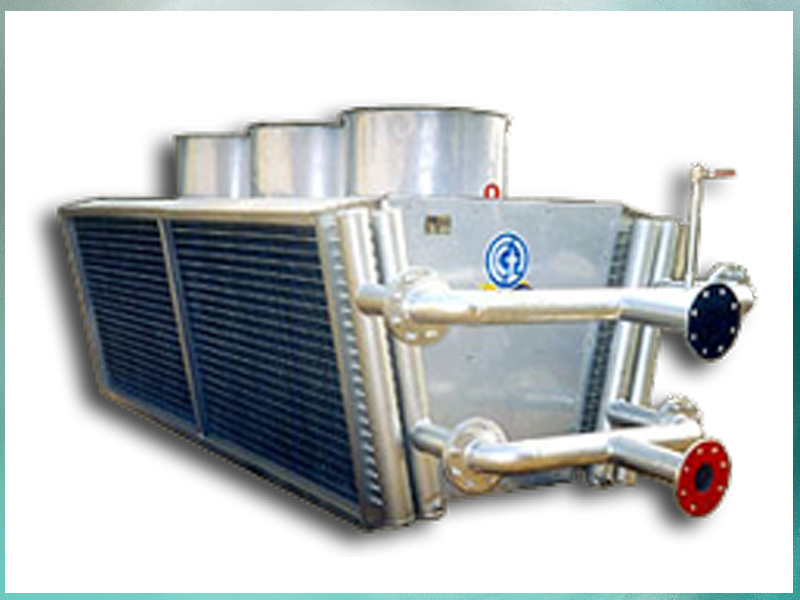

FRP Square Type Cooling Tower

The Square Shape Cooling Towers designed especially for an alternative to round model for selection to our buyers. The FRP consists of Honey comb PVC fills and eliminators in a design that maximizes economy and efficiency and directly driven fan and Motor with spray Nozzles ‘Minimum drift Losses. Hot dipped Galvanized hardware with rectangular casing body in elegant design.

FRP Bottle Shape Cooling Tower

The Round Shape FRP (Fiber glass Reinforced Plastic) also called as Bottle Shape Cooling Tower . The casing and basins are designed to withstand severe vibration, high wind load and to resist corrosion. The FRP consists of Honey comb PVC fills and eliminators in a design that maximizes economy and efficiency and directly driven fan and Motor ‘Minimum drift Losses’ . Uniform distribution of hot water by rotating arm sprinkler. Hot dipped Galvanized hardware to withstand wind forces. The bottle shapemakes possible to provide maximum cooling efficiency in minimum plan area with lower energy consumption.

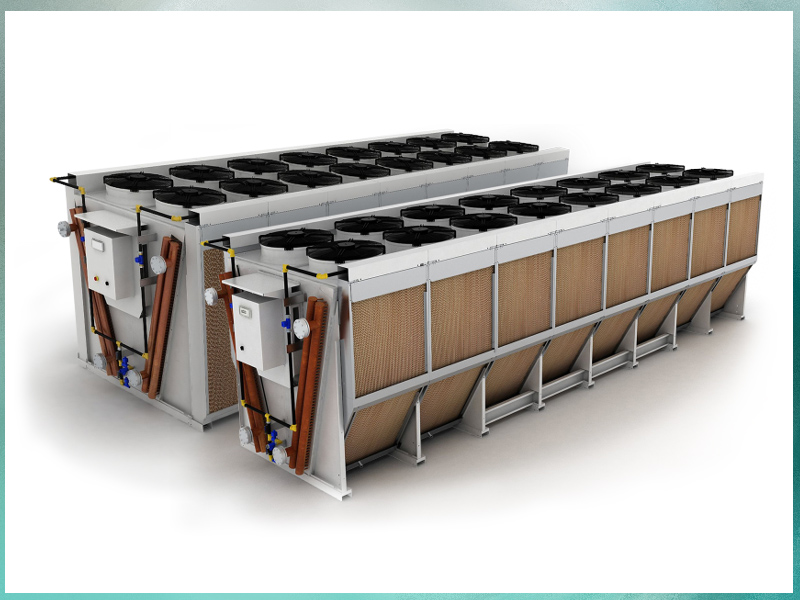

FRP Seamless

We Design and Manufacture a comprehensive Seamless here in India, our designing peoples concentrate much more to develop these kind ofSeamless as per our buyers requirement that have a single piece shell. There are no seems, panels, rivets or plenty of fasteners in this Seamlessand with no compromise of Quality, Competitive price and Elegant look. Contact us for more information on our Seamless We can offer FRP Bottle Shape Induced Draft Cross Flow Counter Flow . Square Shape Induced Draft Cross Flow, Counter Flow. Round Shape Induced Draft Cross Flow,Counter Flow. Rectangular Shape Induced Draft Cross Flow, Counter Flow. FRP Seamless Induced Draft Cross Flow and Counter Flow.

FRP Cooling Tower Casing

We Design and Manufacture a comprehensive Seamless here in India, our designing peoples concentrate much more to develop these kind ofSeamless as per our buyers requirement that have a single piece shell. There are no seems, panels, rivets or plenty of fasteners in this Seamlessand with no compromise of Quality, Competitive price and Elegant look. Contact us for more information on our Seamless We can offer FRP Bottle Shape Induced Draft Cross Flow Counter Flow . Square Shape Induced Draft Cross Flow, Counter Flow. Round Shape Induced Draft Cross Flow,Counter Flow. Rectangular Shape Induced Draft Cross Flow, Counter Flow. FRP Seamless Induced Draft Cross Flow and Counter Flow.

FRP Cooling Tower Fill

Honeycomb PVC Fills are used for extended contact area having high heat transfer efficiency. The crossing of air and water streams in close proximity, which creates a diffuesed turbulence conductive to evaporation and efficient heat transfer. A pre-eminent quality and long life fill consists of modular block of PVC honey combs construction to create prolonged contact time of hot air with water for maximum heat transfer. The air pressure drop through the fill is negligible. The fills available in different flute size like 6mm, 12 mm, 19 mm and 1.2 mm thichness.

FRP Cooling Tower Nozzles

General fill consists of Honeycomb PVC Film type splash deck is modules with high resistant to corrosion and highly efficient for heat transfer water distribution system. The hot water is raised by hot water riser and taken inside by a PVC hot water header inside. Branch distribution pipes fitted with Polypropylene Splash cups / non clogging nozzles are connected to hot water heater and uniform water distribution over entire fill is achieved. It is totaly maintenance free distribution.

FRP Cooling Tower Drift Eliminator

To reduce carry out losses through entrainment of moisure drops in the stream by specially designed drift elimiator made of PVC Fills. Additional PVC eliminator is provided in large capacity cooling towers.

FRP Cooling Tower Drift Eliminator

To reduce carry out losses through entrainment of moisure drops in the stream by specially designed drift elimiator made of PVC Fills. Additional PVC eliminator is provided in large capacity cooling towers.

FRP Cooling Tower Motor

Special low RPM totally enclosed motors of vertical, Flange type with enlarged and treaded shaft and sealed top is supplied with the cooling tower. The motor is also weather proof and in IP-55 construction.

FRP Cooling Tower Supports and Hardware:

All components like tower supports, motor supports, leg supports, etc., are either hot dip galvanized or epoxy coated. Hardware is Galvanized Steel. Stainless Steel or Phosphor Branze hardware can be supplied on request at extra cost.

FRP Cooling Tower Fan

The fan consists of axial propeller fan blades of special alloy aluminium blades of aero dynamic designed axial flow type to achieve high efficiency. Adjustable pitch blades are used for maximum utilization of applied horsepower and connected to a common Aluminum Alloy Hub. The fan is dynamically balanced. FRP fan set can also be supplied on request at extra cost.

FRP Cooling Tower Energy Fans

A new generation, state of the art fans, the energy economy concept. Built with uncompromising international quality standards. Our fans are combination of performance, strength, endurance and reliability.

Design: Frp fan blades have been specially designed aerodynamically for cooling towers. Flow characteristic of the fan outlet ensures an optimum distribution of air across the cooling tower, giving an added benefit to the system

Power Saving: FRP fans are most efficient, consumes upto 30% less power than conventional aluminum alloy / FRP blades. Thus saving in operational cost is enormous.

Light Tough and Strong: Due to considerably lower mass of FRP blades, drives and support frames can be made similar and hence cheaper. FRP blades are made by specially adopted technique. These are hollow and light but are extremely fatigue resistant, tough and strong.

FRP Cooling Tower Blancing: The hub assemblies are balanced dynamically on computerised machine. The blades are matched movement balanced.

FRP Cooling Tower Erosion and chemical Resistance: Fan assembilies provide bvariable pitch angle fan blades for maximum temperature control, continoyus power savings and when needed freeze protection.